In the realm of industrial processes, rotary kilns play a crucial role in various sectors such as cement, metallurgy, chemical industry, and building materials. One essential component of a rotary kiln is the rotary kiln tyre, a key element that contributes to the efficiency and reliability of the kiln operation. In this comprehensive article, we will explore the uses and importance of rotary kiln tyres in different industries, highlighting their role in supporting the functionality of rotary kilns.

Understanding the Rotary Kiln Tyre

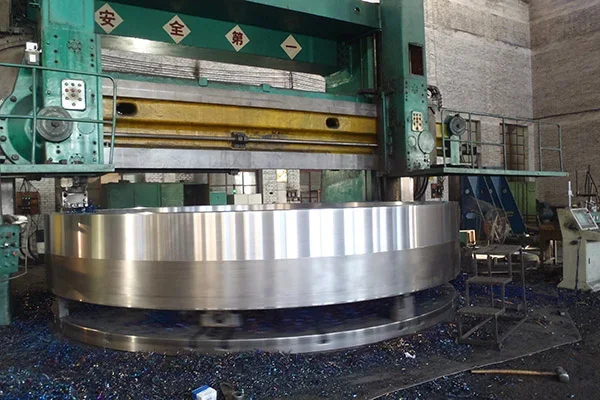

Thehttps://www.special-metal.com/Rotary-kiln-tyre.html, also known as the rotary kiln ring gear, is a large, sturdy ring-shaped component that is mounted on the shell of the rotary kiln. It serves as a support structure for the kiln shell and helps to maintain the proper alignment and rotation of the kiln. The rotary kiln tyre is typically made of high-quality steel and is designed to withstand the high temperatures and mechanical stresses encountered during kiln operation.

Applications of Rotary Kiln Tyres in Various Industries

1. Cement Industry:

In the cement industry, rotary kilns are used for the production of clinker, a key ingredient in cement manufacturing. Rotary kiln tyres play a critical role in supporting the kiln shell and ensuring smooth rotation, which is essential for the efficient production of clinker. The durability and reliability of rotary kiln tyres are crucial for maintaining uninterrupted cement production.

2. Metallurgy:

In the metallurgical industry, rotary kilns are utilized for processes such as roasting, smelting, and calcination of ores and minerals. Rotary kiln tyres provide the necessary support and stability for these high-temperature processes, ensuring the proper functioning of the kiln and the quality of the end products. The robust construction of rotary kiln tyres makes them ideal for withstanding the harsh conditions of metallurgical operations.

3. Chemical Industry:

The chemical industry often employs rotary kilns for processes like thermal decomposition, pyrolysis, and chemical reactions. Rotary kiln tyres play a crucial role in these applications by maintaining the alignment and stability of the kiln, which is essential for achieving precise temperature control and reaction efficiency. The chemical industry relies on the reliable performance of rotary kiln tyres to ensure the success of various production processes.

4. Building Materials:

In the building materials industry, rotary kilns are used for the production of materials such as lime, gypsum, and aggregates. Rotary kiln tyres are integral to these processes, providing the necessary support for the kiln shell and ensuring the consistent rotation required for efficient material processing. The versatility and durability of rotary kiln tyres make them indispensable in the production of building materials.

Benefits of Rotary Kiln Tyres

1. Stability and Alignment:

Rotary kiln tyres help maintain the stability and alignment of the kiln shell, preventing issues such as misalignment and uneven rotation. This ensures smooth operation and optimal performance of the rotary kiln.

2. Durability and Reliability:

The robust construction of rotary kiln tyres enables them to withstand high temperatures, mechanical stresses, and wear over prolonged periods of operation. Their durability and reliability contribute to the longevity of rotary kilns in various industries.

3. Efficient Heat Transfer:

Rotary kiln tyres facilitate efficient heat transfer within the kiln, allowing for precise temperature control and uniform heating of materials. This is crucial for achieving the desired reactions and product quality in industrial processes.

Conclusion

In conclusion, the use of rotary kiln tyres is essential in various industries such as cement, metallurgy, chemical industry, and building materials. These sturdy components play a critical role in supporting the operation of rotary kilns, ensuring stability, alignment, and efficiency in industrial processes. The versatility, durability, and reliability of rotary kiln tyres make them indispensable for the success of kiln operations in diverse applications. By understanding the uses and benefits of rotary kiln tyres, industries can maximize the efficiency and productivity of their rotary kiln operations.

China Special Metal Group Limited (CSM), a supplier of steel casting for metallurgical machinery, cement mining machinery, building material machinery, ceramic industry, forging industry, shipbuilding industry and chemical industry, is dedicated to offering high-quality of steel casting, high-precision machining products and welded fabrications to valued customers all over the world.

If you are looking for rotary kiln tyres solutions or related technical support, welcome to contact us.

E-mail:sales@special-metal.com